Sputtering is an indispensable process in semiconductor manufacturing, used to prepare thin film materials. In actual production, atoms on the target material are escaped onto a monocrystalline silicon substrate by ion bombardment, forming a metal film.

The target material is a key core material used in the sputtering process. At present, the target material industry is monopolized and controlled by large enterprises in the United States and Japan. If other manufacturers want to stand out in the fierce competition, they need to come from behind in terms of technology and quality strength. Quality control cannot be achieved without high-precision measurement technology.

Ningbo Jiangfeng Electronic Materials Co., Ltd. is a core enterprise in domestic integrated circuit materials. Its research and development and production of ultra-high purity metal sputtering targets fill the gap in this field in China and meet the constantly expanding market demand.

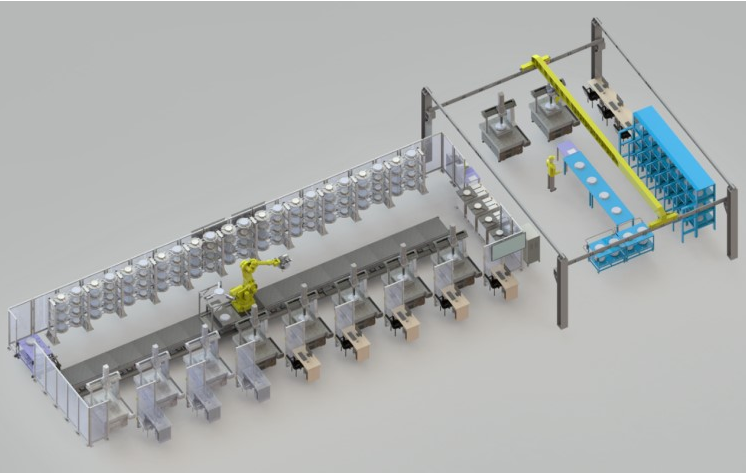

In order to improve the efficiency of target size measurement, shorten the delivery cycle, and alleviate the pressure of labor shortage, Jiangfeng Electronics officially launched the automated testing introduction project on December 6, 2021. This project is provided by Sirui with dense detection equipment and Modebao with flexible automation solutions, working together to break through industry bottlenecks.

This automation solution uses the Sirui CROMA686 coordinate system as the measurement model. CROMA adopts a control system specially designed by Hexconn, providing 21 error space correction techniques and automatic tuning functions to ensure the dynamic performance and measurement accuracy of the machine.

In addition, CROMA is equipped with multiple core technologies to provide guarantees for precision measurement. Advanced all aluminum technology, precision 60 ° triangular beam technology, high-precision air flotation system, and multiple core technologies imported from Europe ensure its measurement accuracy.

The meticulously manufactured CROMA three coordinate system provides a solid guarantee for stable measurement. The material selection is based on the group's supply chain platform, allowing CROMA to choose high-quality parts. High standard process flow and equipment are used in manufacturing to ensure machine quality.

In this scheme, the CROMA model is equipped with an automation module system, which can achieve information interaction with robots, loading and unloading systems, and related sensors. Through automated management software, automatically complete workpiece measurement, analyze and judge workpiece inspection results, and generate inspection reports and data as needed.

Sirui measurement provides precise measurement support for this three coordinate flexible automated testing line project. Afterwards, Sirui will continue to pay attention to the measurement needs of the manufacturing industry, continuously innovate, and help relevant manufacturing industries achieve efficient and accurate measurement to make greater contributions.