Large, dual head discharge machining tool

EDNC28

Automation, digitization, and modularization

In recent years, with the continuous improvement of living standards, traditional functions of automobiles have been unable to meet the needs of consumers, and the requirements for performance, appearance, personalization, and other aspects have become increasingly high. The development cycle of new car models has also been continuously shortened, driving the continuous growth of market demand for automotive interior and exterior decoration molds and supporting products.

The trend of integrating car lights, bumpers, and other parts with the integration of body die-casting has increasingly high requirements for the processing quality and efficiency of large molds. Traditional domestically produced dual head spark machines are no longer able to meet the processing needs of leading customers in the industry. Based on the absolute advantages of Makino's discharge machining technology and performance, Makino has launched the EDNC28 large dual head discharge machining machine tool, Assist Chinese mold customers in winning more high-quality orders in the fiercely competitive international market.

PART 01

200% increase in efficiency

50% reduction in delivery time

The EDNC28 machine tool adopts a design of dual heads and dual electrical boxes, with two sets of Hyper i systems for independent control of the left and right heads. The discharge machining process does not affect each other, which means a 50% reduction in discharge time and a 200% increase in productivity. Half of the time can achieve the same results, better helping customers cope with the production pressure caused by shortened delivery times.

PART 02

Large and flexible

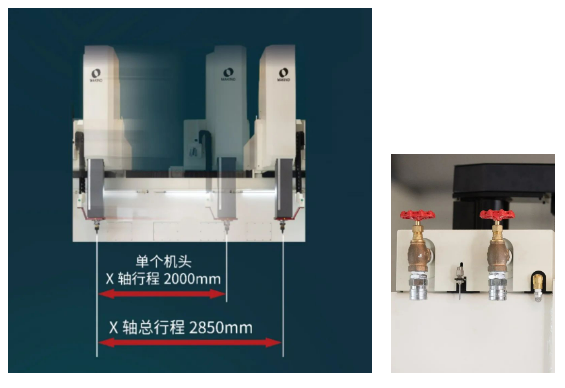

As a large dual head discharge machining machine, EDNC28 gives the impression of being 'big', and 'big' brings customers unlimited possibilities for machining. Machine tool stroke (X * Y * Z) 2850mm * 1150mm * 800mm; It can meet the size requirements of discharge machining for various large molds.

Although EDNC28 has a large size, its machining is very flexible. The maximum stroke of a single head X-axis is 2000mm, and the minimum distance between two heads is 850mm. This can meet the conventional discharge machining needs of two heads distributed on both sides of the process, as well as the machining needs of two heads moving to one side for centralized discharge under special circumstances. This design makes machining more flexible and diverse.

The oil flushing valves on both sides of the machine tool not only meet the requirements of general mold immersion processing methods, but also take into account the special needs of customers using oil flushing processing methods, and the design is more in line with customer usage habits.

PART 03

ES200A power supply+H E. A.T. technology, worry free processing

The EDNC28 is equipped with the latest ES200A digital power supply from Makino, which provides more precise current and voltage control. Especially in graphite discharge machining, it reduces electrode loss and shortens processing time. Even when machining both ends simultaneously, due to Makino's high rigidity casting structure, stable processing accuracy can be guaranteed.

H. E.A.T technology, worry free processing.

HS-Rib high-speed jumping, EDNC28 machine head can reach a maximum jumping speed of 20m/min, and the efficiency of rib processing has achieved a landmark improvement. The high-speed jumping function can effectively discharge slag to stabilize the processing state and shorten the processing time.

Hyper Cut ultra cutting machining, real-time detection of discharge process status, elimination of machining efficiency and loss caused by abnormal discharge, stable discharge status, and increased machining efficiency.

The Super Spark function further shortens the rough machining time and improves the efficiency of discharge machining while ensuring machining accuracy according to machining requirements.

The Makino Hyper i system, connected through multiple windows, can quickly and easily perform all operations from installation to processing. Based on Makino's powerful processing condition database, even apprentices with limited experience in discharge machining can develop high-quality processing programs.

PART 04

Other advantages

PART 05

Specification parameters